3D Printing allows to produce objects in three-dimensional shapes by commanding a 3D printer through a computer interface. The 3D printer prints the desired shape from a 3D CAD file by dispensing the material onto a platform and printing the object layer by layer. The way in which it prints differs from conventional ways, which are concerned with the cutting or extraction of the 3D object after printing. The growth of 3D printing for commercial applications is becoming a worldwide trend. The global market for 3D printers continues to rise year on year, thus gaining momentum for 3D printing services. 3D printing is making a giant impact from healthcare to automobile, architecture, commercial and manufacturing sectors in Pune. In Pune city there are various industries who are looking for 3D Printing services.

Architecture sector: 3D printing is allowing architects greater freedom in planning and presenting to clients. Another economic advantage is the possibility of getting building models fabricated quickly and cheaply. Physical 3D printed building models can create a better sense for the clients to visualize the projects and easily invest. As architects can move through limitations posed by 2D models, the approvals and buy-ins from clients are hastened, and projects are expedited. With the large pool of 3D printing materials, they can communicate their idea succinctly and explore many geometries of buildings and apartments.

Automobile Industry: At the present time, and in the view of the mechanical engineers, it is a sunny day for them to have spare parts for automobiles that are light but sturdy with 3D printing. They visualize complex structures for testing and produce final parts through rapid prototyping. Their integration into manufacture has saved time and guaranteed great finishes of products produced. Soon, it will be used commercially for spare parts. There are top automobile industries in Pune like Tata Motors, Mahindra, Mercedes Benz etc.

Commercial good: Pune is fast being considered as an attractive market for commercial products. Whether 3D printing is in electronics, entertainment, sports, or any other utility products, fulfilling market demands has just become easier. There may be no limit to the number of products that can be made through additive manufacturing technology. Designers, manufacturers, and hobbyists can now customize and deliver products per requesting demand. Even having a 3D printed selfie as a life-long memory is turning into a possibility with the existence of a desktop 3D printer costing a few thousand rupees.

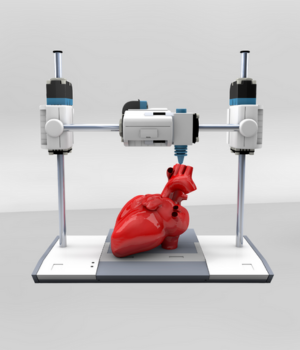

Medical Industry: One of the greatest impacts of 3D printing is patient-specific implants as well as tools and equipment customization. 3D printing has made it possible to customize prosthetics and implants like never before. It is also creating surgical tools, tailor-made for ease of use for both the patient and surgeon. Furthermore, with the drop in 3D printer prices in India, hospitals and other facilities in the medical research industry are exploring different applications for 3D printing. 3D Printing is also seen to be applicable in Skull surgery and orthopedic surgeries.

Conclusion:

3D printing is revolutionizing various industries by providing greater flexibility, efficiency and customization. In architecture, it allows architects to quickly create physical models, which helps in better client presentations and faster project approvals. The automobile industry benefits from rapid prototyping and the creation of lightweight yet durable spare parts. The commercial sector, including electronics and entertainment, has seen an explosion in customized products, making it easier to meet diverse consumer demands. Additionally, the medical field has been greatly impacted, with personalized implants and surgical tools improving patient care and outcomes. As the cost of 3D printers continues to fall, more industries and sectors in cities like Pune are adopting this technology, paving the way for an increasingly innovative future.