The 3D printing industry in India is on the cusp of a remarkable transformation, fueled by visionary innovation and an insatiable thirst for efficiency. By 2025, the industry is set to redefine possibilities, promising a future brimming with creativity and precision. As we edge closer to 2025, the growth trajectory of 3D printing in India is nothing short of phenomenal. Fueled by daring innovations and a collective push towards sustainability and customization, this technology is breaking barriers and unlocking doors to opportunities previously deemed unimaginable. From precision-engineered aircraft components to life-saving medical implants, the possibilities of 3D printing are only limited by our imagination.

Market Growth Projections for 2025

1. Market Valuation and Exponential Growth

India’s 3D printing market is poised to expand at a dazzling CAGR of 20-25%, catapulting the industry into a new era of growth. This surge is driven by a deep-seated desire for faster, cost-effective, and customized solutions across industries.

2. Catalysts for Growth

-

- Automotive Marvels: The sector is embracing 3D printing for revolutionary lightweight designs and bespoke prototypes, enhancing both efficiency and aesthetics.

- Healthcare Breakthroughs: Personalized prosthetics, life-saving implants, and intricate dental structures are transforming patient care like never before.

- Aerospace Dreams: The sky is no longer the limit as 3D printing enables the creation of intricate, high-strength components for aviation and defense.

3. Policy Support: A Game-Changer

Initiatives like Make in India and Startup India have ignited a fervor for local manufacturing and innovation, making 3D printing more accessible and fostering a thriving ecosystem.

Industry Trends: A Peek into the Future

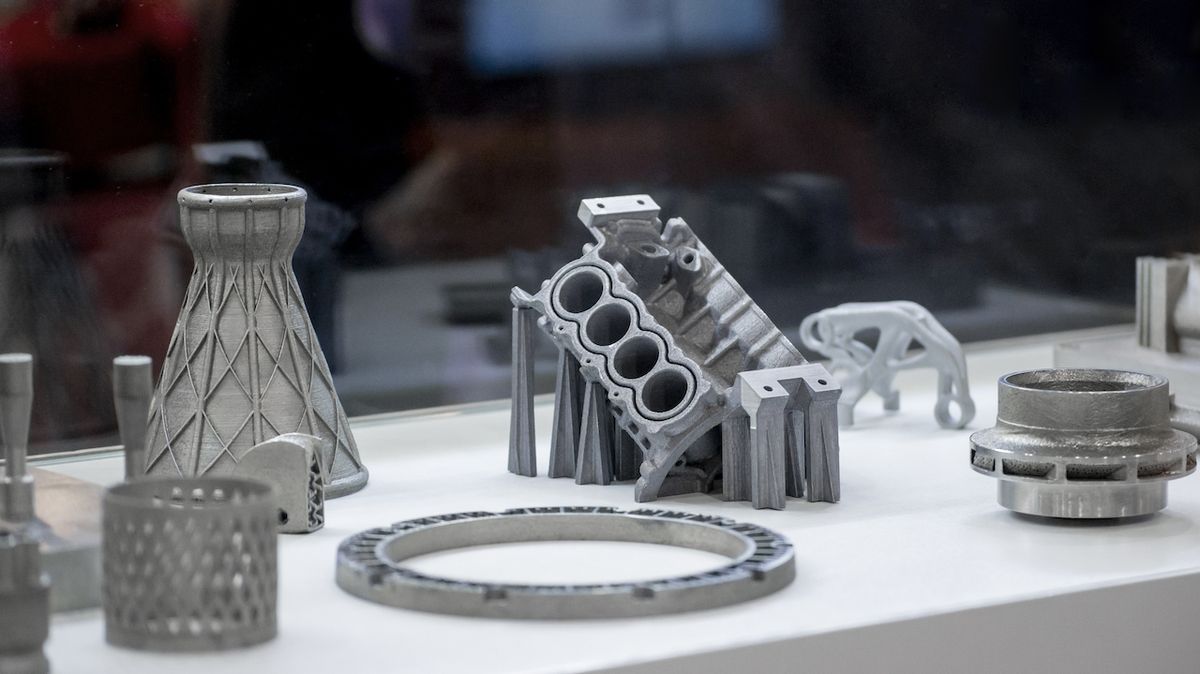

1. Metal 3D Printing: The Dawn of Durability

The rise of metal 3D printing is nothing short of a technological marvel, enabling the creation of durable, high-performance parts that were once inconceivable.

2. Sustainability: The Soul of Innovation

In an era where ecological consciousness reigns supreme, 3D printing is embracing sustainability with ferocious determination, using eco-friendly materials and minimizing waste.

3. The Democratization of Technology

Affordable desktop 3D printers are becoming harbingers of change, empowering small businesses, hobbyists, and visionaries to unleash their creativity.

4. On-Demand Magic

Additive manufacturing services are reshaping business models, allowing companies to access cutting-edge technology without the burden of exorbitant investment.

5. Material Alchemy

The innovation in exotic materials—from bio-compatible polymers to high-strength composites—heralds a future where the only limit is imagination.

Overcoming Hurdles

Despite its spectacular potential, the road to 3D printing’s dominance in India is not without its challenges. These hurdles, however, are not insurmountable—they represent opportunities to refine processes, improve accessibility, and drive further innovation.

1. High Initial Investments

The cost of acquiring advanced 3D printers and materials can be prohibitive for small and medium-sized enterprises (SMEs). To address this, the industry needs collaborative models, such as leasing options, shared infrastructure, and government subsidies, to make 3D printing more accessible.

2. Lack of Awareness

For many businesses, the capabilities and applications of 3D printing remain shrouded in mystery. Bridging this knowledge gap through awareness campaigns, workshops, and training programs is crucial to unlocking the technology’s full potential.

3. Scarcity of Skilled Talent

The absence of a robust talent pool skilled in additive manufacturing and 3D modeling tools poses a challenge. Educational institutions and private training centers must collaborate to offer specialized courses and hands-on training to cultivate the next generation of 3D printing experts.

4. Material Limitations

Although there has been progress in developing diverse and high-performance materials, further R&D is needed to create cost-effective, sustainable, and versatile materials suitable for a broader range of applications.

5. Regulatory Uncertainty

The lack of clear regulatory frameworks for 3D-printed products, especially in critical sectors like healthcare and aerospace, could hinder growth. Establishing robust guidelines and standards will provide much-needed clarity and boost confidence in adopting this technology.

By addressing these challenges with a combination of policy interventions, educational initiatives, and industry collaboration, India can unlock the full transformative potential of 3D printing.

Conclusion

India stands at the threshold of a 3D printing revolution, a moment teeming with promise and possibility. By 2025, this transformative technology is set to redefine how we create, enabling industries to achieve precision, efficiency, and sustainability like never before.

The growth of 3D printing in India is not just a technological phenomenon—it is a cultural shift toward innovation and bold thinking. With the support of progressive government policies, an expanding ecosystem of startups, and the tireless ingenuity of Indian talent, the country is poised to emerge as a global leader in additive manufacturing.

As the industry continues to evolve, it carries with it the potential to revolutionize not only manufacturing but also education, healthcare, and even art. In this journey, the challenges we face are merely stepping stones toward a brighter, smarter, and more sustainable future.

The story of 3D printing in India is one of dreams realized, boundaries pushed, and a future built layer by layer. By embracing this cutting-edge technology, India is not just shaping products—it is shaping a legacy of innovation for generations to come.

Services we offer at Kreate 3D in Pune, Mumbai, Nashik, Aurangabad, Nagpur, Kolhapur, Goa, Belagavi

FDM 3D Printing Services, SLA 3D Printing Services, SLS 3D Printing Services, MJF 3D Printing Services, Metal 3D Printing Services, Vacuum Casting Services , 3D Scanning Services, Reverse Engineering Services & All Type Of Prototyping Services. Zortrax FDM 3D Printer (M300 Dual,M300 Plus, M200 Plus), Formlabs SLA 3D Printer (Form 4, Form 4L,Form 4B, Form 4BL), Thor 3D Scanner (Calibry, Calibry Mini).