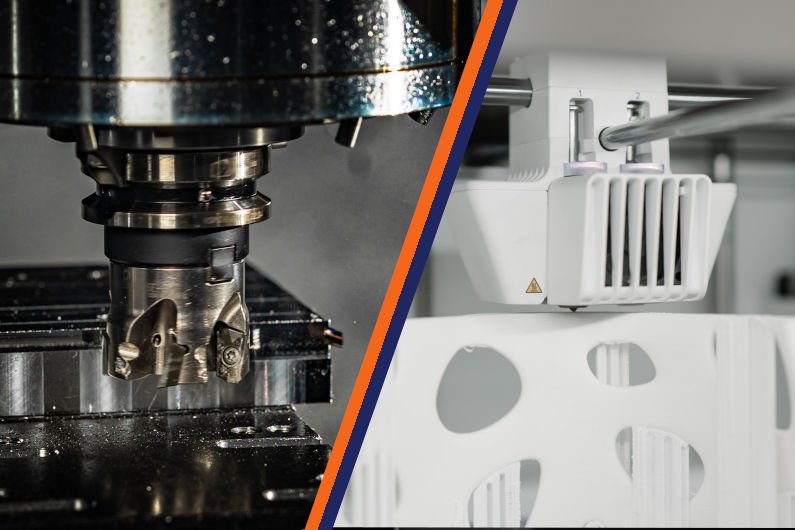

The manufacturing industry has seen remarkable advancements over the years, and two of the most popular technologies are 3D printing and CNC machining. Both offer unique advantages, making them suitable for different applications. Let’s dive into their key differences to help you decide which one suits your project needs.

1. What is 3D Printing?

3D printing, also known as additive manufacturing, builds objects layer by layer using materials like plastics, resins, and metals. It relies on CAD models to create intricate designs with minimal waste.

Applications:

- Prototyping

- Custom parts

- Lightweight components

- Complex geometries

Advantages:

- Minimal material waste

- Customization-friendly

- Faster prototyping

Disadvantages:

- Limited material options compared to CNC machining

- Lower strength in certain cases

2. What is CNC Machining?

CNC (Computer Numerical Control) machining is a subtractive manufacturing process. It starts with a block of material (metal, plastic, etc.) and removes material to achieve the desired shape.

Applications:

- High-precision parts

- Industrial-grade tools

- Metal components

Advantages:

- Superior strength and durability

- High precision and accuracy

- Wide material compatibility

Disadvantages:

- High material waste

- Slower for intricate designs

3. Key Differences Between 3D Printing and CNC Machining

| Factor | 3D Printing | CNC Machining |

|---|---|---|

| Process | Additive (layer-by-layer) | Subtractive (material removal) |

| Material Waste | Minimal | High |

| Complexity | Excels in intricate designs | Limited by tool access |

| Speed | Faster for prototypes | Slower for detailed parts |

| Cost | Affordable for low-volume production | Cost-effective for large volumes |

| Strength | Depends on material and design | Typically higher |

4. When to Choose 3D Printing

- Low-volume production: Ideal for prototypes or custom parts.

- Complex geometries: Works well for intricate or hollow designs.

- Budget-friendly: Suitable for projects with minimal material needs.

5. When to Choose CNC Machining

- High precision: Required for industrial applications or aerospace.

- Durability: Needed for tools and metal components.

- Larger batches: Cost-efficient for mass production.

Services we offer at Kreate 3D in Pune, Mumbai, Nashik, Aurangabad, Nagpur, Kolhapur, Goa, Belagavi

FDM 3D Printing Services, SLA 3D Printing Services, SLS 3D Printing Services, MJF 3D Printing Services, Metal 3D Printing Services, Vacuum Casting Services , 3D Scanning Services, Reverse Engineering Services & All Type Of Prototyping Services. Zortrax FDM 3D Printer (M300 Dual,M300 Plus, M200 Plus), Formlabs SLA 3D Printer (Form 4, Form 4L,Form 4B, Form 4BL), Thor 3D Scanner (Calibry, Calibry Mini).