In the rapidly evolving landscape of electric vehicles (EVs), innovation is the driving force that propels industries forward. One such game-changing technology is 3D printing, which has started revolutionizing various industries, including automotive manufacturing. For India, a country poised to become a global hub for EV production, 3D printing offers transformative possibilities. This blog delves into how 3D printing can reshape the EV manufacturing ecosystem in India.

What is 3D Printing?

3D printing, also known as additive manufacturing, is a process of creating three-dimensional objects from digital designs by layering material sequentially. Unlike traditional subtractive manufacturing, where material is removed to form a shape, 3D printing builds objects layer by layer, leading to minimal waste and exceptional precision.

The Rise of Electric Vehicles in India

India is on the cusp of an electric vehicle revolution, driven by increasing environmental concerns, government policies, and a push towards sustainable mobility. However, manufacturing EVs remains a challenge due to the high costs of components, limited availability of raw materials, and reliance on imports. Here’s where 3D printing steps in as a potential game-changer.

How 3D Printing Enhances EV Manufacturing

- Rapid Prototyping:

- 3D printing accelerates the development of EV components by enabling rapid prototyping.

- Engineers can create, test, and refine parts within days, significantly reducing the time-to-market.

- Cost Efficiency:

- By using 3D printing, manufacturers can produce lightweight components at a fraction of the cost.

- The technology minimizes material waste, leading to reduced expenses.

- Customizability:

- 3D printing allows for unparalleled customization of parts, catering to specific design needs and consumer preferences.

- Sustainability:

- Additive manufacturing aligns with the sustainability goals of EV production by reducing waste and enabling the use of recycled materials.

- Localized Manufacturing:

-

With 3D printing, Indian manufacturers can localize production, reducing dependency on imports and lowering the carbon footprint associated with transportation.

-

Key Applications of 3D Printing in EV Manufacturing

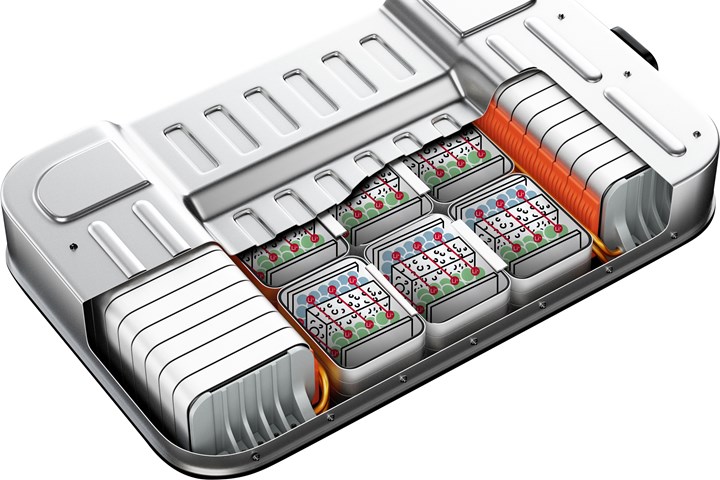

Battery Enclosures

Durable and heat-resistant 3D printed battery enclosures ensure safety and efficiency in EVs.

Lightweight Components

From chassis parts to suspension systems, 3D printing helps produce lighter components.

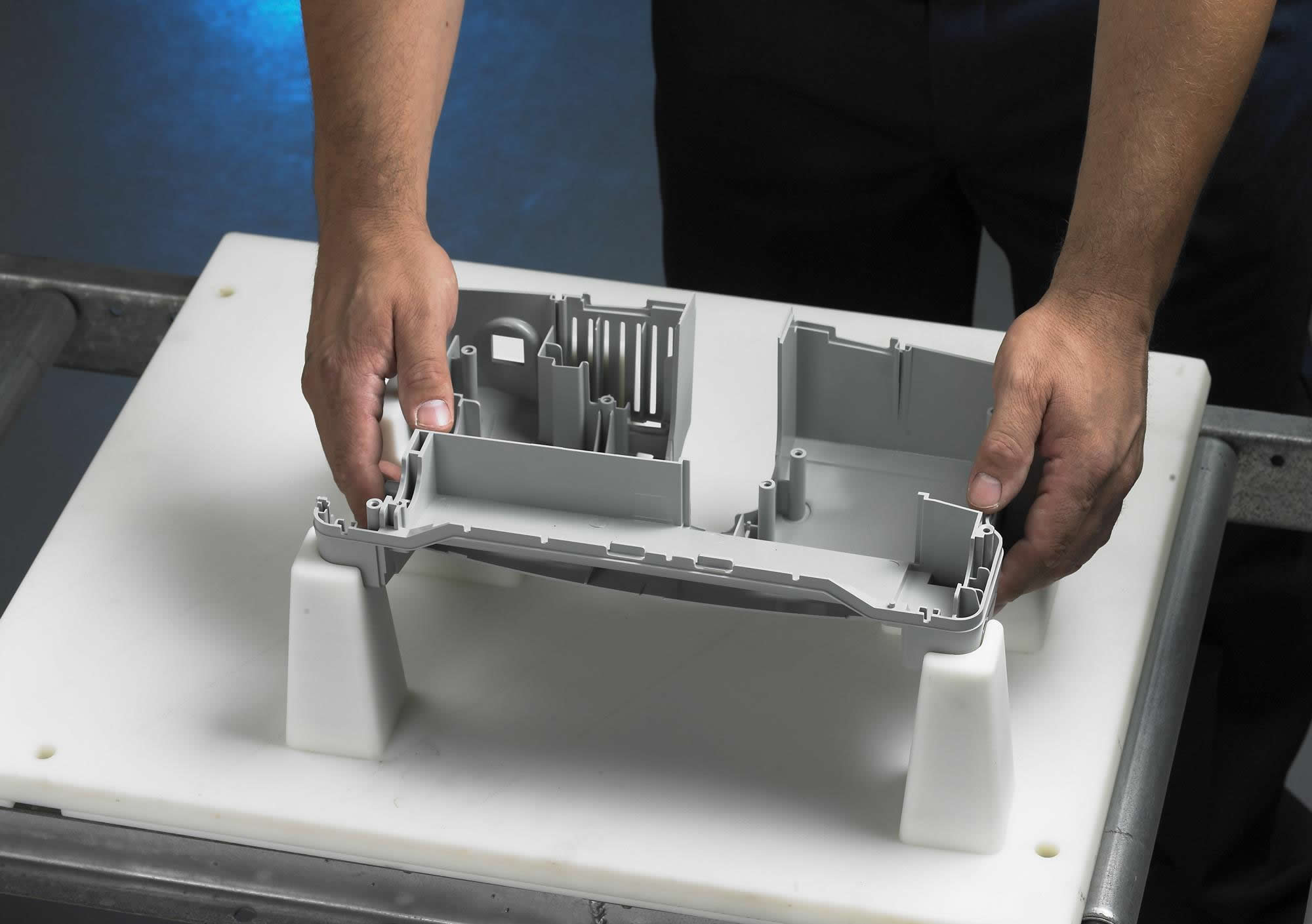

Tooling and Fixtures

Additive manufacturing enables the creation of precise tooling and fixtures for assembling EVs.

Interior Customization

3D printing makes it possible to craft intricate interior designs, providing a premium feel.

Challenges to Adoption in India

Despite its potential, the adoption of 3D printing in EV manufacturing faces hurdles:

-

High Initial Investment: Setting up 3D printing facilities requires significant capital.

-

Skilled Workforce: There is a need for trained professionals to operate and maintain 3D printers.

-

Material Availability: Access to advanced materials suitable for 3D printing is limited in India.

The Road Ahead

The Indian government’s push towards Atmanirbhar Bharat (self-reliant India) aligns perfectly with the advantages of 3D printing. Incentives for adopting advanced manufacturing technologies and collaborations between academia, startups, and industries can accelerate the integration of 3D printing into EV manufacturing.

Conclusion

3D printing is more than just a manufacturing tool; it is a catalyst for innovation and sustainability. By embracing 3D printing, India can not only overcome the challenges in EV production but also emerge as a leader in the global EV market. The future of EV manufacturing in India is intertwined with the advancements in 3D printing technology, promising a long drive into a sustainable and innovative future.

As the EV industry accelerates, 3D printing stands ready to steer the journey. Are Indian manufacturers ready to hit the gas on this transformative technology? Only time will tell, but one thing is certain—3D printing is here to redefine the road ahead.

Services we offer at Kreate 3D in Pune, Mumbai, Nashik, Aurangabad, Nagpur, Kolhapur, Goa, Belagavi

FDM 3D Printing Services, SLA 3D Printing Services, SLS 3D Printing Services, MJF 3D Printing Services, Metal 3D Printing Services, Vacuum Casting Services , 3D Scanning Services, Reverse Engineering Services & All Type Of Prototyping Services. Zortrax FDM 3D Printer (M300 Dual,M300 Plus, M200 Plus), Formlabs SLA 3D Printer (Form 4, Form 4L,Form 4B, Form 4BL), Thor 3D Scanner (Calibry, Calibry Mini).