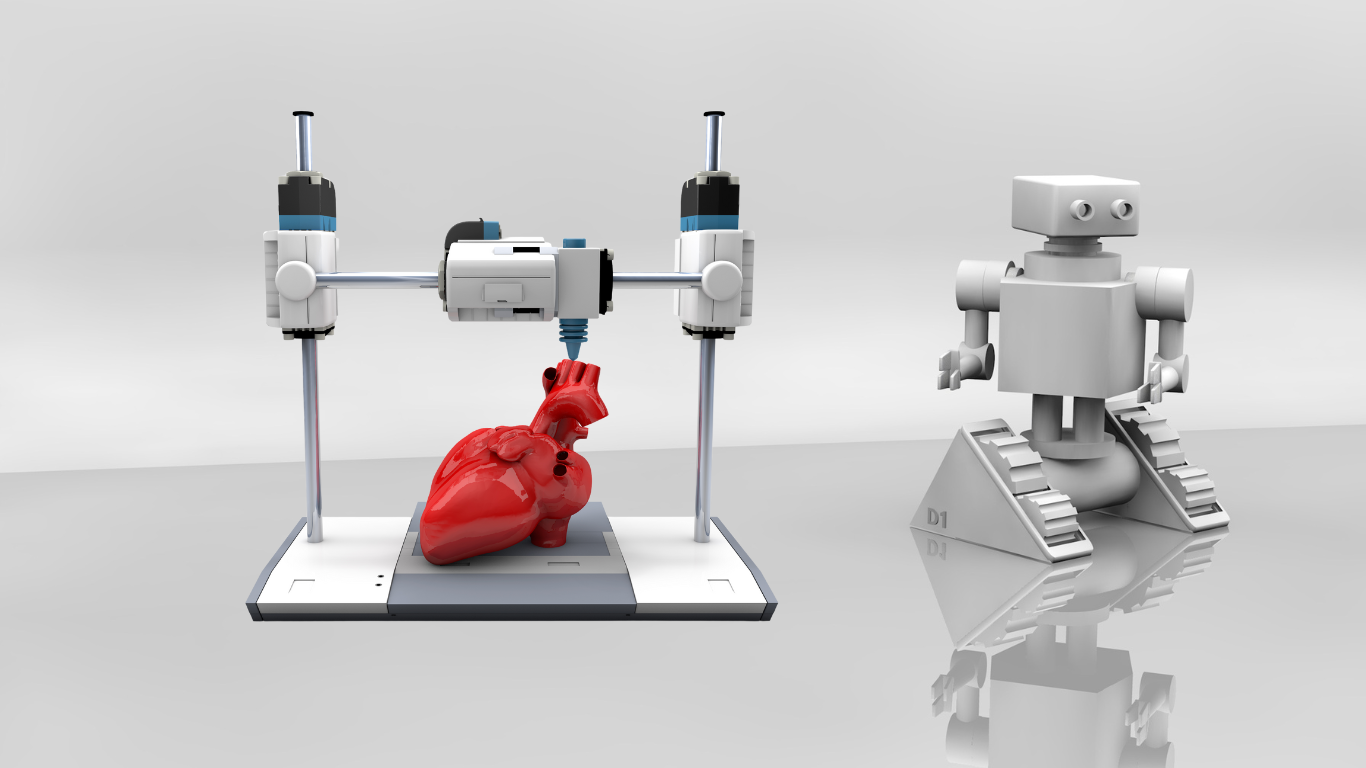

In today’s rapidly changing technical industries, the combination of artificial intelligence (AI) and 3D printing triggers revolutionary changes in sectors. Not only this makes production processes easier, but also increases innovation, efficiency and responsiveness. As we fly into this technologies, it quickly becomes clear that we are at the future of a new age of production.

Revolution design and production:

Traditionally, 3D printing has been of wide range of benefits in small production and prototyping industry. When AI is used with 3D printing, it adds extra features to the 3D Printing process. The AI software can scan a lot of information to help in product design, identify patterns and customize structures for maximum performance. This means that designers can produce more innovative and functional designs that were previously impossible.

For example, generic design is AI-based; engineers provide given parameters and limitations and after that, the program comes up with some design options. It not only saves time but also encourages creativity as it brings about options that won’t be conceived.

Optimize the manufacturing efficiency:

The combination of AI and 3D printing increases production efficiency to a large degree. AI can predict maintenance needs for printers, reduce shutdowns and can keep the equipment longer. AI can also customize print settings such as temperature, speed and physical usage by analyzing data from printed products, resulting in less waste and rapid treatment time.

Secondly, AI can potentially automate the installation and monitoring process, reducing labor expense in manual operation. By doing this, human operators can focus on more strategic and creative roles and, overall, lead to a more dynamic and effective workforce.

Scale of customization:

One of the most exciting possibilities for AI and 3D print combination is adaptable on a large scale. Companies move quickly from a one-size-fits-all approach to fit the unique needs of individual consumers. With AI’s ability to read consumer trends and data, companies are able to quickly adapt production and design processes to fit individual needs.

3D printing facilitates this change with permission to produce one-off products without having to invest vast amounts of money in tools and production lines. Whether medical device or fashion parts, AI and 3D printing Ally enable adaptation both as a possibility and an affordable reality.

Future prospects:

Looking ahead, AI and 3D printing collaboration is even more promising to develop. With advanced materials that can respond more intelligently to AI-targeted instructions more versatile and dynamic manufacturing processes, the possibilities are endless. The technologies call for a greener and more innovative method of production that addresses key problems such as shortages of resources and environmental issues.

Investments in such constructive collaboration build smart factories step by step, wherein automation and AI-driven intelligence bring revolution to traditional method of production. The new technology will not only reshape production efficiency but also produce best solutions in other domains.

Conclusion:

Overall, AI and 3D printing combine synergy that signals the arrival of new manufacturing time saving innovation, functionality as well as customization. When companies continue to explore and develop to capitalize on these innovations, we can count on for searching out spectacular break-through innovations, which transformed the manner in which material is thought of manufactured as well as accessed. Accepting to perform the evolution can become important for adhesives whose existence in ever-growing global continues to be at stakes.

Are you equipped to step into the future of production? Let’s include those technological advancements together and form the future of production!