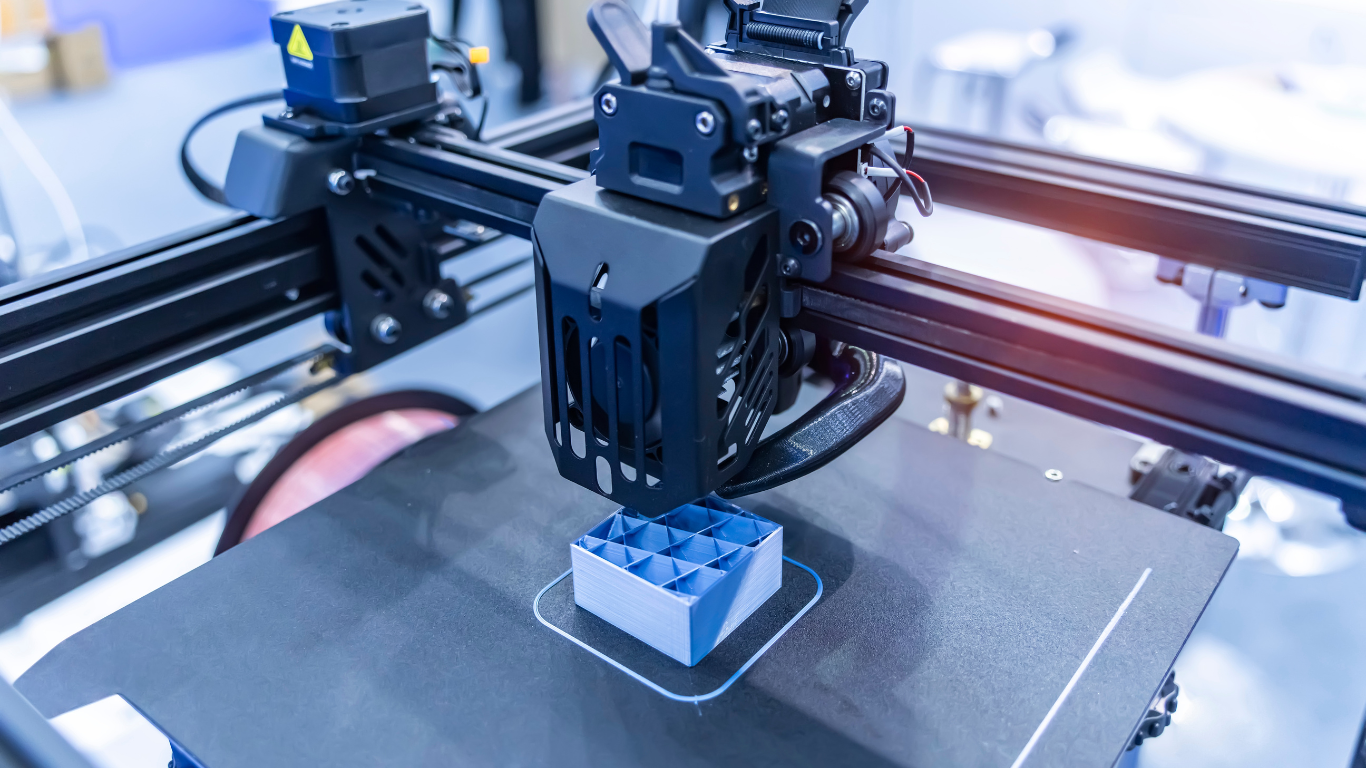

Engineering is a field that constantly evolves with technological advancements, and one such breakthrough that has revolutionized the industry is 3D printing. Also known as additive manufacturing, 3D printing has transformed how engineers design, prototype, and manufacture products, offering unparalleled speed, efficiency and cost-effectiveness. But why has 3D printing become an indispensable tool in engineering? Let’s explore the key reasons

1. Rapid Prototyping and Product Development

Traditional manufacturing methods often require expensive molds and tools to create prototypes, which can be both time-consuming and costly. With 3D printing, engineers can create functional prototypes within hours, allowing for faster iteration and testing. This speeds up the overall product development cycle, enabling companies to bring innovations to market quicker than ever before.

2. Cost-Effective Manufacturing

3D printing eliminates the need for large-scale production runs and expensive machinery. Engineers can produce custom parts on demand without the waste associated with traditional subtractive manufacturing processes. This not only reduces material costs but also minimizes waste, making it a more sustainable option.

3. Complex Designs Made Easy

Engineering often involves intricate designs that are difficult or even impossible to manufacture using conventional methods. 3D printing allows for highly complex geometries, such as lattice structures and internal channels, without additional manufacturing steps. This opens new possibilities for innovative product designs, particularly in aerospace, automotive, and medical industries.

4. Customization and Personalization

Industries like automotive, healthcare, and aerospace require highly customized solutions. 3D printing enables engineers to create tailor-made components that meet specific requirements without extra costs. Whether it’s a unique engine part, a customized prosthetic limb, or a lightweight aerospace component, 3D printing allows for precise customization.

5. Stronger and Lightweight Components

Advancements in 3D printing materials, such as high-performance polymers, metals, and composite materials, have allowed engineers to create parts that are both lightweight and durable. This is particularly crucial in sectors like aerospace and automotive, where reducing weight leads to better fuel efficiency and overall performance.

6. Reduced Lead Times in Manufacturing

Traditional manufacturing requires multiple stages, from design to mold creation and assembly. With 3D printing, engineers can bypass several steps, significantly reducing lead times. This is especially beneficial when producing spare parts or critical components that are needed urgently in industries such as oil & gas, automotive, and defense.

7. Sustainability and Waste Reduction

3D printing is inherently more sustainable compared to traditional manufacturing. Since it is an additive process, it only uses the material necessary to build the component, reducing excess waste. Furthermore, many 3D printing materials are now biodegradable or recyclable, making it an eco-friendly option for engineering firms looking to reduce their carbon footprint.

8. Enhancing Education and Research

In the field of engineering education, 3D printing has become an invaluable tool for students and researchers. It allows students to visualize complex concepts and bring their ideas to life, making learning more interactive and hands-on. Universities and R&D labs use 3D printing for testing innovative materials, designs, and structures before full-scale production.

Conclusion

The integration of 3D printing in engineering is no longer a luxury—it has become a necessity. From rapid prototyping and cost savings to complex designs and sustainability, 3D printing is revolutionizing the way engineers work. As technology continues to advance, we can expect even greater innovations, making 3D printing an essential part of the engineering world.

Whether you’re an engineering firm looking to streamline production or a researcher exploring new possibilities, investing in 3D printing services can unlock countless opportunities. The future of engineering is being built layer by layer, and 3D printing is leading the way!